河北沼阳环境科技有限公司HEBEI ZHAOYANG ENVIRONMENTAL TECHNOLOGY CO.,LTD

- Basic info

- Registration info

- Trade info

- Factory info

- Main Markets:

Africa , Americas , Asia , Caribbean , East Europe , Europe , Middle East , North Europe , Oceania , Other Markets , West Europe , Worldwide

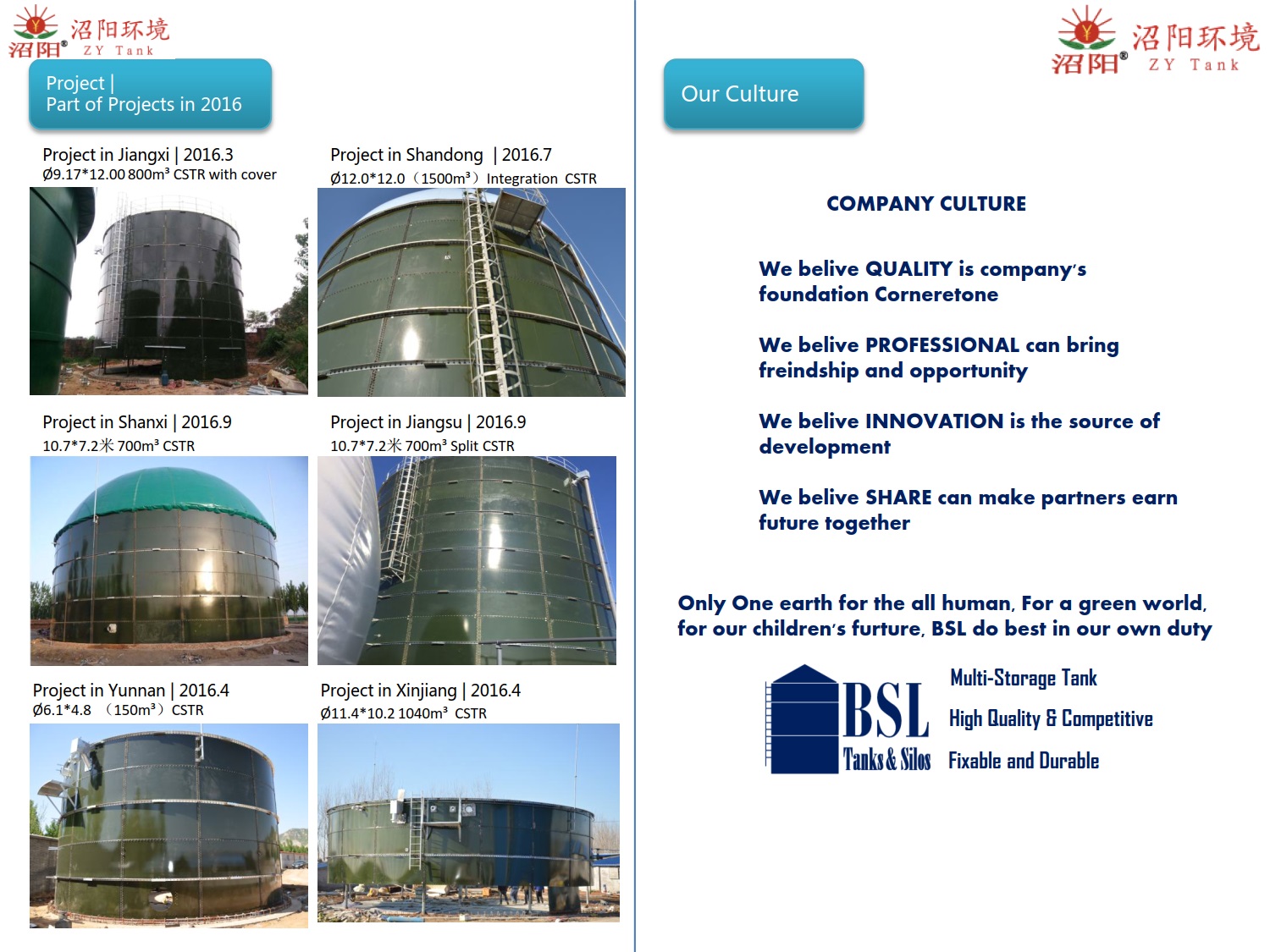

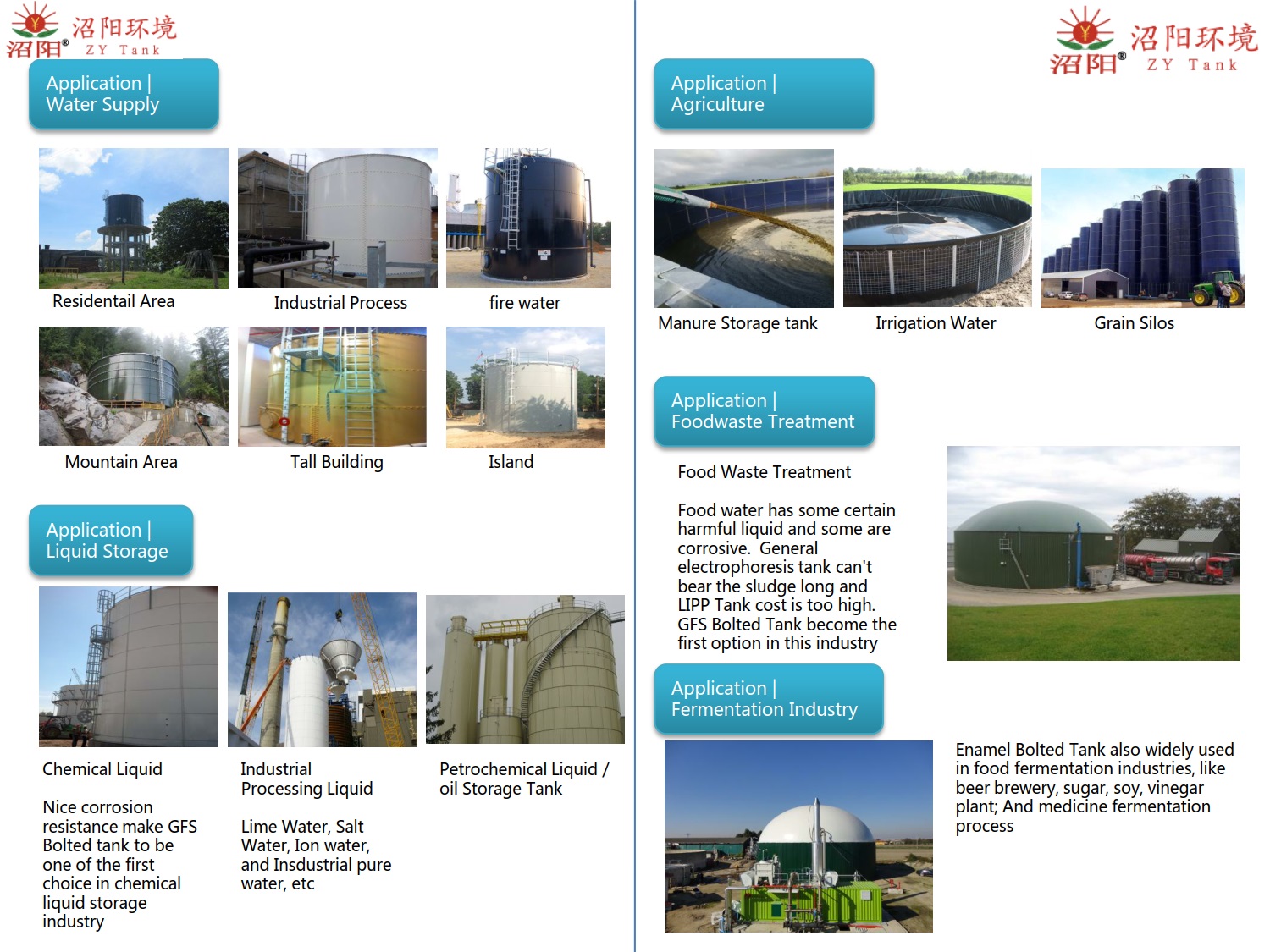

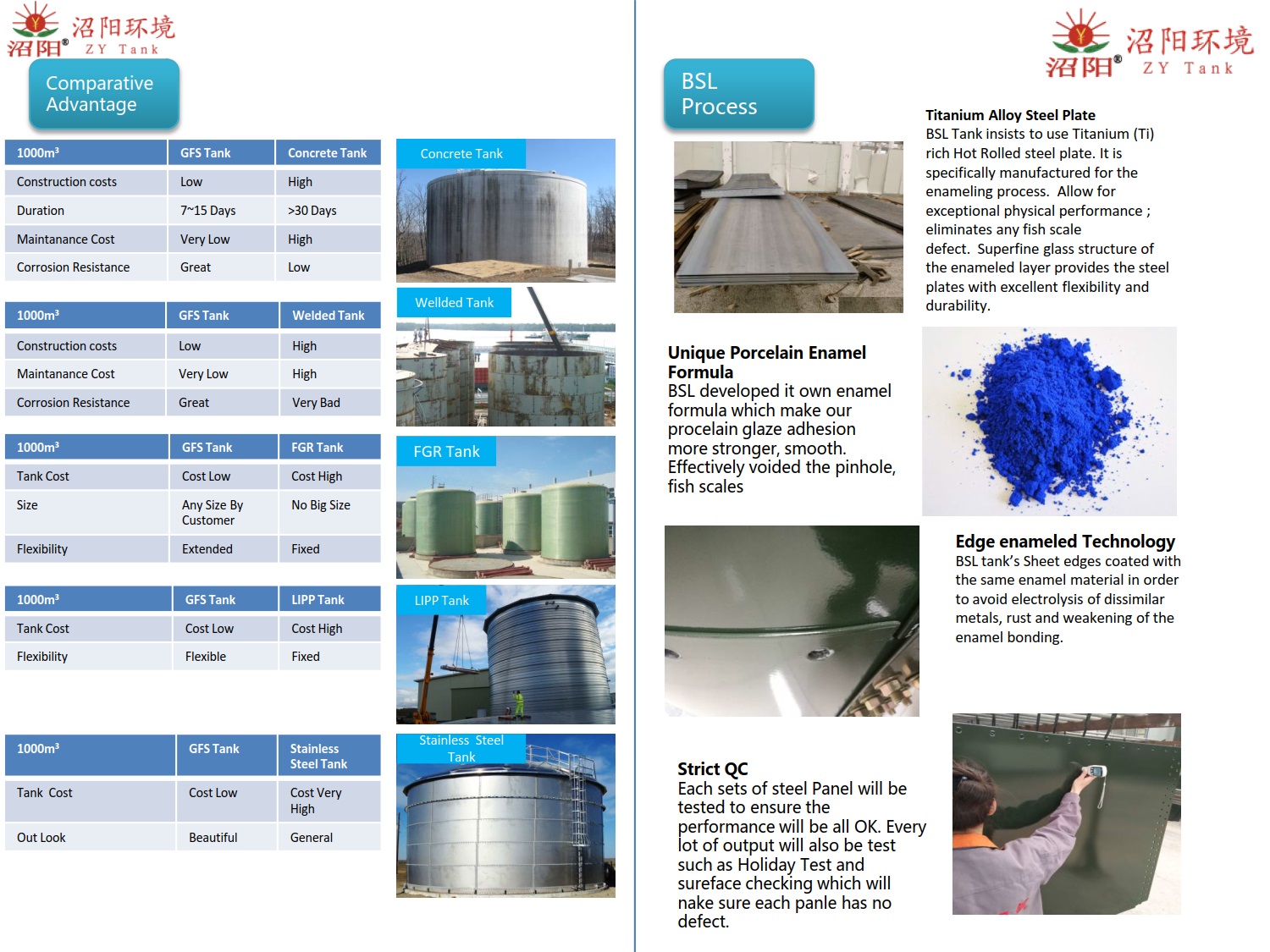

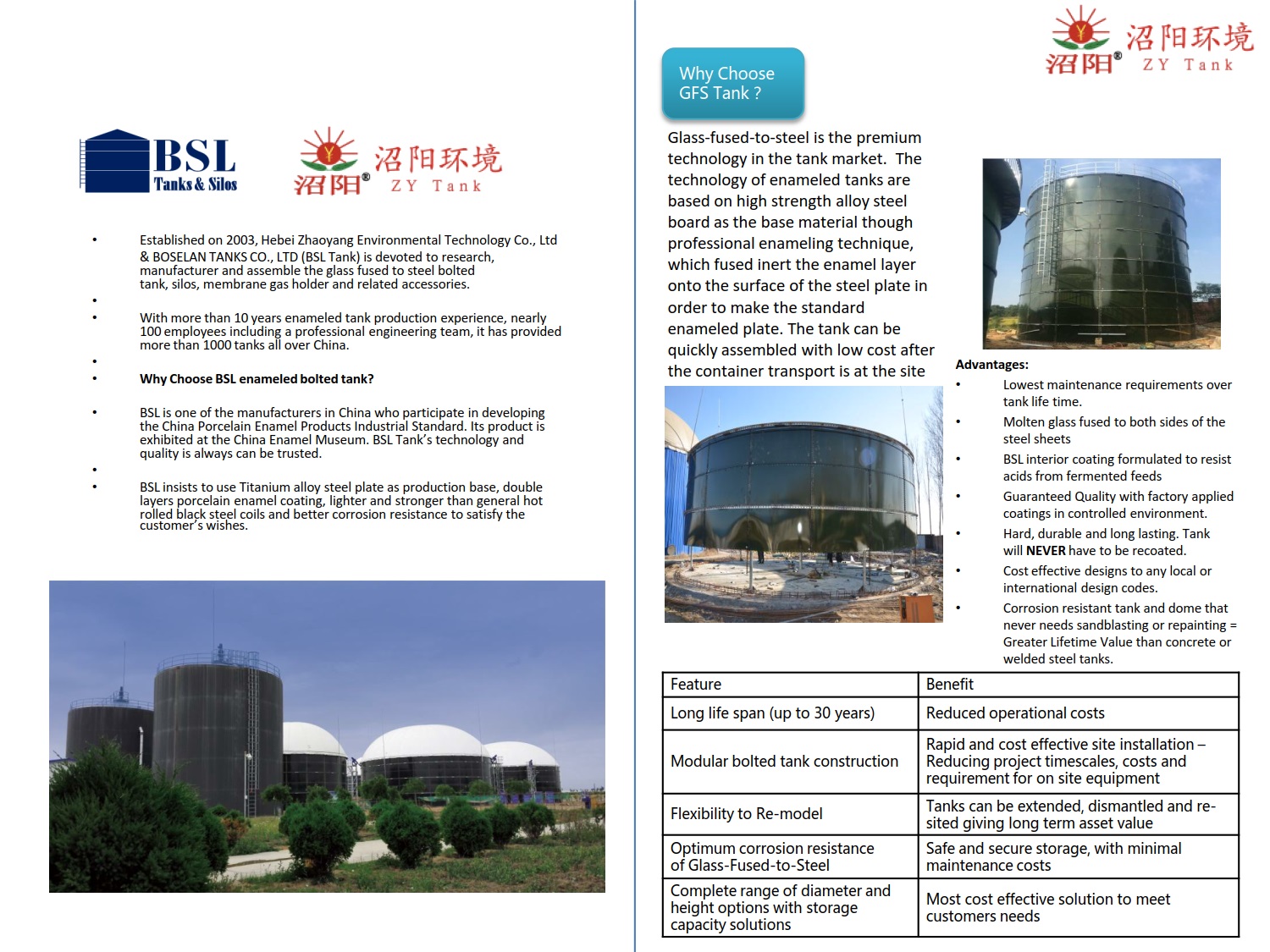

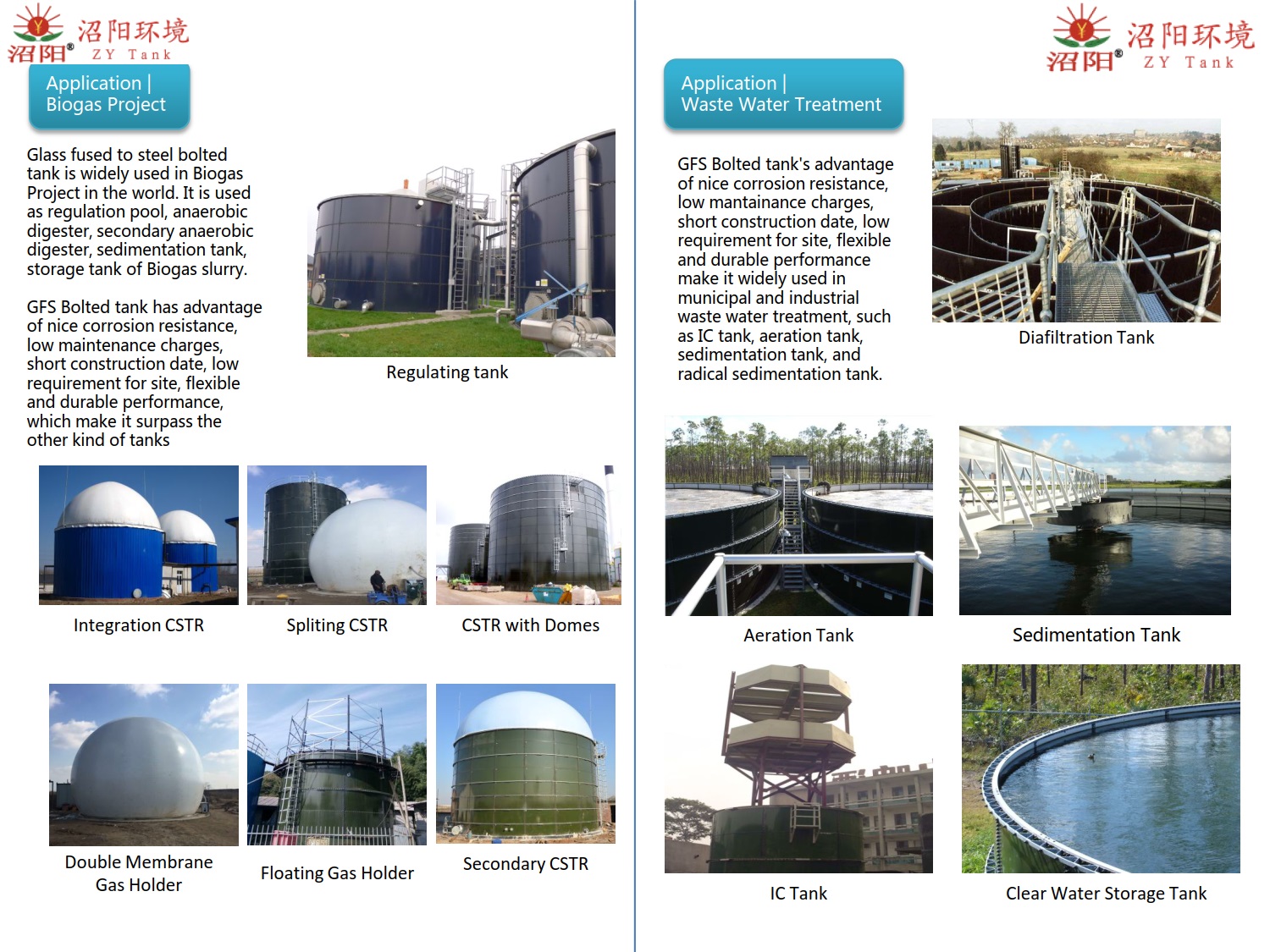

Product/Service:About US : Established on 2003, Beijing BOSELAN Environmental Technology Co., Ltd (BSL TANK) is devoted to research, manufacturer and assemble the glass fused to steel bolted tank, silos and related accessories. With more than 10 years enameled bolted tank production experience, nearly 100 employees including a professional engineer team, it has provided more than 2000 tanks through out of China. Why Choose BSL enameled bolted tank? BSL is one of the manufacturers in China who participate in developing the China Porcelain Enamel Products Industrial Standard. Its product is exhibited at the China Enamel Museum in Shanghai. BSL Tank’s technology and quality is always can be trusted. BSL insist to use Titanium alloy steel plate as production base, double layers porcelain enamel coating, lighter and stronger than general hot rolled black steel coils and better corrosion resistance to satisfy the customer’s wishes. What is Glass Fused to Steel Bolted Tank (Enamel Bolted Tank). Glass fused to steel ( GFS ) tanks / glass lined to steel ( GLS ) tanks / Enamel tanks, are commonly used for portable water storage, wastewater treatment, farm bio-energy, agriculture dry bulk storage and many other application areas. GFS tanks main features are: 1. Superior anti - corrosion performance. 2. At least 30 years’ product service life. 3. Very easy and quick for installation. 4. Tank volume can be expanded and removable. 5. Very low maintenance cost after installation. Based in China, equipped with most advanced production lines, designed according to AWWA D103-09 / ISO 28765, apply international QC standards, BSL tanks can provide superior tank solution with most economic cost, maximize customers' cost performance. With rapid development these years, BSL tanks mission is to be the leader of glass fused to steel tank industry, and enable more customers have opportunity to choose better GFS tanks with more reasonable cost. BSL Enameled bolted tank advantages: Higher Quality - Factory applied glass-fused-to-steel bolted tank and thermo-set baked on modified epoxy tank lining systems outperform than air cured factory and field applied coatings. Faster - Modular pre-engineered steel tanks and dedicated fabrication plants offer quick delivery and easier assembly. Expandable – Bolted assembly tank can be disassembled and add-assembled to easily change the tank size to satisfy the further requirement of the project. Lower cost –Competitive price based on China, world factory; Long lifecycle (up to 30years), and assembly with bolt reduced the maintenance costs, provided significantly lower life cycle costs and subsequent savings over the tank life. Flexibility - Capacities from 1 m3 to 45,000 m3. A wide variety of configurations are available. Markets Served: Biomass Energy Project -Whole set of Anaerobic Digester tank Water treatment industry -Municipal project-Potable Water tank, sewage tank -Industrial waste water treatment -Sea water cleaning treatment - Leachate water tank -Other water treatment Agriculture -Irrigation project -irrigation water tank Fire Protection -Fire water tank Industrial Liquids project -Industrial liquid tank Petrochemical Industry -Petrochemical liquid tank Power Generation- -Cooling water tank -Leachate liquid tank Food Industry -Edible Liquid tank (Beer, soy, vinegar, etc) Dry Bulk -Grain storage silos Biogas is produced by anaerobic digestion of organic waste from the food industry and from agricultural by-products. The utilization of organic material from plants and animal waste adds additional value to farming and food processing. BSL supplies individual components such as specialized storage solutions, digesters(厌氧反应器), thermal storage systems, digestate dryers(沼渣烘干机), agitators(搅拌机) and heat exchangers(热交换器). Titanium Rich Hot Rolled Carbon Steel Plates and Sheets Researching and developing special titanium alloy plates for enamel, which breaks the bottleneck of double-faced enamel of steel plates; 1. Plates and sheets used in the construction of the tank shell, tank floor (if required) and tank roof (if required) shall meet or exceed structural requirements of the standards of AWWA D103, latest edition. 2. Design requirements for High Strength Hot Rolled carbon steel shall be minimum ASTM A572 Grade 50, ASTM A516 GR. 70, ASTM A1011/A1018 all grades, or special Titanium rich carbon steel ART310 specifically prepared for enameling/glass lining application with the following min. mechanical properties 4. Titanium (Ti) Rich Hot Rolled Carbon Steel with Min. Yield Strength of: 320Mpa (46.5 KSI or 46500 PSI) – 350Mpa (50.5 KSI or 50500 PSI). The purpose is to have less austenite which can contain much more hydrogen during the enamel firing/curing and to create preferable Ti-precipitates during the hot rolling process. Use of Titanium Rich Hot-Rolled Carbon Steel eliminates so called “Fish Scale” defect and it works extremely well with the application of the catalytic Nickel Oxide primer or NiO (Nickel Oxide) mixed with base coat of glass frit. Specially developing brand new porcelain glaze formula for titanium alloy steel plates, which directly upgrades the acid-base resistance of enameled steel plates from B+ grade to double-A grade of international standard; Accessories: Strengthen angle steel : Improving stirrup angle steel for installation, which improves L50 equal angle steel to L100*63*6 angle steel, with its strength improved for many times; Roof options: BSL tanks can be adapted to accept a wide range of roof options. Each roof has specific features and benefits which make them unique and suitable for different specifications and project requirements. Typical roof options include: -Fabric Roof / Membrane domes Economical, for low profile tanks in low wind areas -Geodesic Domes / Aluminum alloy structure domes Top-of-the-line, clear span, non-corroding all aluminum structure -Open Top / without covers Standard for sewage and wastewater treatment applications -Enameled Steel Roof Applied to agitator covers Cathode Protection: Cathode protection system is fitted uses sacrificial anodes to protect the reinforcing bars, mitigate corrosion and provide protection to internal submerged surfaces of the tank. It is incorporated into the ZhaoYang tank’s warranty Ladders, Cage and platform: Tank ladders are constructed of hot dipped galvanized hot rolled carbon steel rails, rungs cages and step off platforms. Ladders with locking safety cage doors are available. Walkways, railings and staircase: An option to the standard ladder and cage is a walkway and staircase. CST walkways are hot-dip galvanized steel and are appropriate for situations when regular overhead tank Gravity Vent Protection: Positive and Negative pressure protectors are designed to allow for air exchange during filling and emptying. They are equipped with corrosion-resistant bird and insect screens. Sidewall Man-way: Tank man-way is designed in according with AWWA D103 Standards. They are 24 inches (61 cm), 30 inches (76 cm) or 36 inches (91 cm) in diameter and are manufactured with hot-dip galvanized steel or stainless steel. Bolts and Caps Sealer: Cooperatively developed special self-locking bolts with durable plastic bolt caps offer added protection to the external hardware against weather and corrosion. For specialized applications, sealer alternatives are available. Flange, Nozzle & Baffle: Flange, Nozzles and baffles are available depending on tank use and specifications. Engineering flexibility allows these accessories to be incorporated into overall tank design Sealants: Cooperatively developed special sealant weatherproof sealants in the temperature range of -40℃-60℃; About US : Established on 2003, Beijing BOSELAN Environmental Technology Co., Ltd (BSL TANK) is devoted to research, manufacturer and assemble the glass fused to steel bolted tank, silos and related accessories. With more than 10 years enameled bolted tank production experience, nearly 100 employees including a professional engineer team, it has provided more than 2000 tanks through out of China. Why Choose BSL enameled bolted tank? BSL is one of the manufacturers in China who participate in developing the China Porcelain Enamel Products Industrial Standard. Its product is exhibited at the China Enamel Museum in Shanghai. BSL Tank’s technology and quality is always can be trusted. BSL insist to use Titanium alloy steel plate as production base, double layers porcelain enamel coating, lighter and stronger than general hot rolled black steel coils and better corrosion resistance to satisfy the customer’s wishes. What is Glass Fused to Steel Bolted Tank (Enamel Bolted Tank). Glass fused to steel ( GFS ) tanks / glass lined to steel ( GLS ) tanks / Enamel tanks, are commonly used for portable water storage, wastewater treatment, farm bio-energy, agriculture dry bulk storage and many other application areas. GFS tanks main features are: 1. Superior anti - corrosion performance. 2. At least 30 years’ product service life. 3. Very easy and quick for installation. 4. Tank volume can be expanded and removable. 5. Very low maintenance cost after installation. Based in China, equipped with most advanced production lines, designed according to AWWA D103-09 / ISO 28765, apply international QC standards, BSL tanks can provide superior tank solution with most economic cost, maximize customers' cost performance. With rapid development these years, BSL tanks mission is to be the leader of glass fused to steel tank industry, and enable more customers have opportunity to choose better GFS tanks with more reasonable cost. BSL Enameled bolted tank advantages: Higher Quality - Factory applied glass-fused-to-steel bolted tank and thermo-set baked on modified epoxy tank lining systems outperform than air cured factory and field applied coatings. Faster - Modular pre-engineered steel tanks and dedicated fabrication plants offer quick delivery and easier assembly. Expandable – Bolted assembly tank can be disassembled and add-assembled to easily change the tank size to satisfy the further requirement of the project. Lower cost –Competitive price based on China, world factory; Long lifecycle (up to 30years), and assembly with bolt reduced the maintenance costs, provided significantly lower life cycle costs and subsequent savings over the tank life. Flexibility - Capacities from 1 m3 to 45,000 m3. A wide variety of configurations are available. Markets Served: Biomass Energy Project -Whole set of Anaerobic Digester tank Water treatment industry -Municipal project-Potable Water tank, sewage tank -Industrial waste water treatment -Sea water cleaning treatment - Leachate water tank -Other water treatment Agriculture -Irrigation project -irrigation water tank Fire Protection -Fire water tank Industrial Liquids project -Industrial liquid tank Petrochemical Industry -Petrochemical liquid tank Power Generation- -Cooling water tank -Leachate liquid tank Food Industry -Edible Liquid tank (Beer, soy, vinegar, etc) Dry Bulk -Grain storage silos Biogas is produced by anaerobic digestion of organic waste from the food industry and from agricultural by-products. The utilization of organic material from plants and animal waste adds additional value to farming and food processing. BSL supplies individual components such as specialized storage solutions, digesters(厌氧反应器), thermal storage systems, digestate dryers(沼渣烘干机), agitators(搅拌机) and heat exchangers(热交换器). Titanium Rich Hot Rolled Carbon Steel Plates and Sheets Researching and developing special titanium alloy plates for enamel, which breaks the bottleneck of double-faced enamel of steel plates; 1. Plates and sheets used in the construction of the tank shell, tank floor (if required) and tank roof (if required) shall meet or exceed structural requirements of the standards of AWWA D103, latest edition. 2. Design requirements for High Strength Hot Rolled carbon steel shall be minimum ASTM A572 Grade 50, ASTM A516 GR. 70, ASTM A1011/A1018 all grades, or special Titanium rich carbon steel ART310 specifically prepared for enameling/glass lining application with the following min. mechanical properties 4. Titanium (Ti) Rich Hot Rolled Carbon Steel with Min. Yield Strength of: 320Mpa (46.5 KSI or 46500 PSI) – 350Mpa (50.5 KSI or 50500 PSI). The purpose is to have less austenite which can contain much more hydrogen during the enamel firing/curing and to create preferable Ti-precipitates during the hot rolling process. Use of Titanium Rich Hot-Rolled Carbon Steel eliminates so called “Fish Scale” defect and it works extremely well with the application of the catalytic Nickel Oxide primer or NiO (Nickel Oxide) mixed with base coat of glass frit. Specially developing brand new porcelain glaze formula for titanium alloy steel plates, which directly upgrades the acid-base resistance of enameled steel plates from B+ grade to double-A grade of international standard; Accessories: Strengthen angle steel : Improving stirrup angle steel for installation, which improves L50 equal angle steel to L100*63*6 angle steel, with its strength improved for many times; Roof options: BSL tanks can be adapted to accept a wide range of roof options. Each roof has specific features and benefits which make them unique and suitable for different specifications and project requirements. Typical roof options include: -Fabric Roof / Membrane domes Economical, for low profile tanks in low wind areas -Geodesic Domes / Aluminum alloy structure domes Top-of-the-line, clear span, non-corroding all aluminum structure -Open Top / without covers Standard for sewage and wastewater treatment applications -Enameled Steel Roof Applied to agitator covers Cathode Protection: Cathode protection system is fitted uses sacrificial anodes to protect the reinforcing bars, mitigate corrosion and provide protection to internal submerged surfaces of the tank. It is incorporated into the ZhaoYang tank’s warranty Ladders, Cage and platform: Tank ladders are constructed of hot dipped galvanized hot rolled carbon steel rails, rungs cages and step off platforms. Ladders with locking safety cage doors are available. Walkways, railings and staircase: An option to the standard ladder and cage is a walkway and staircase. CST walkways are hot-dip galvanized steel and are appropriate for situations when regular overhead tank Gravity Vent Protection: Positive and Negative pressure protectors are designed to allow for air exchange during filling and emptying. They are equipped with corrosion-resistant bird and insect screens. Sidewall Man-way: Tank man-way is designed in according with AWWA D103 Standards. They are 24 inches (61 cm), 30 inches (76 cm) or 36 inches (91 cm) in diameter and are manufactured with hot-dip galvanized steel or stainless steel. Bolts and Caps Sealer: Cooperatively developed special self-locking bolts with durable plastic bolt caps offer added protection to the external hardware against weather and corrosion. For specialized applications, sealer alternatives are available. Flange, Nozzle & Baffle: Flange, Nozzles and baffles are available depending on tank use and specifications. Engineering flexibility allows these accessories to be incorporated into overall tank design Sealants: Cooperatively developed special sealant weatherproof sealants in the temperature range of -40℃-60℃;

Conference:Showroom:Website: - Year Established:

----

Capital:RMB -----

Company Address: - Main Markets:

Africa , Americas , Asia , Caribbean , East Europe , Europe , Middle East , North Europe , Oceania , Other Markets , West Europe , Worldwide

Total Annual Sales Volume (Million US $):Above -- Million

Export Percentage:--

- No. of Production Lines:

--

Factory Size (Sq.meters):-- square meters

Factory Location:

Registration info

Video Info